Preventative Maintenance &

Deep Optical Cleaning

Don't let dust destroy your investment. Our 25-point maintenance service restores brightness, prevents overheating, and extends the lifespan of your projectors by up to 40%.

The Silent Killer of Projectors

Projectors are essentially high-powered light cannons that generate immense heat. To stay cool, they pull in vast amounts of air—hundreds of cubic feet per minute for larger venue models. In classrooms and offices, this air is filled with dust, chalk particles, and microscopic fibres.

Over time, these particles bypass basic electrostatic filters and coat the delicate optical components inside. This creates an insulating layer that traps heat, essentially wrapping your expensive DMD chips and polarizers in a wool blanket. The cooling fans spin faster to compensate, pulling in more dust, creating a destructive cycle that leads to:

-

Premature Lamp/Laser Failure: Light sources burn out 40% faster when running 10°C above optimal temp.

-

Dull, Yellow Images: Organic LCD panels degrade under heat, turning whites into a sickly yellow.

-

Catastrophic Overheating: Mainboards warp and BGA solder joints fracture, killing the unit instantly.

-

"White Dot" DMD Death: Micromirrors seize due to thermal stress, creating a "starry night" effect that ruins the picture.

Asset Protection

"A standard service costs <10% of replacement."

Clogged & Dim

Bright & Clear

"A standard service costs less than 10% of a replacement projector, yet restores 90% of its original factory brightness."

Technology-Specific Maintenance Risks

Different projection technologies fail in distinct ways when neglected. Understanding these specific risks is key to protecting your assets.

3LCD (Epson, Sony, NEC)

"Polarizer Burn" & "Yellowing"

3LCD projectors rely on organic polarizers and LCD panels. When filters clog, internal airflow drops. Dust settles on these panels, acting as insulation. The intense light beam then "cooks" the panel, causing a permanent yellow or purple stain on the image. This organic degradation is irreversible once it starts.

Consequence: Requires an expensive Optical Engine replacement (often £400+).

DLP (BenQ, Optoma, Dell)

"White Dots" & "Shattered Wheels"

DLP chips (DMDs) have millions of micro-mirrors. When thermal paste dries out and fans clog, the chip overheats, causing mirrors to stick in the 'on' position (white dots). Additionally, soot buildup on the colour wheel can cause imbalance, leading to vibration, noise, and eventually the wheel shattering inside the unit.

Consequence: DMD chips are costly components. Prevention is significantly cheaper.

Laser & Liquid Cooled

"Coolant Failure" & "Phosphor Decay"

High-end laser units (Panasonic/Christie) often use liquid cooling loops. Neglect leads to coolant evaporation or radiator blockages. If the laser bank overheats, the phosphor wheel degrades rapidly, causing permanent dimming and colour shifting that cannot be fixed by a simple lamp swap.

Consequence: Total unit write-off. Laser banks are rarely replaceable economically.

The "Maintenance-Free" Myth: Advanced Laser Projector Care

Many IT managers purchase laser projectors believing the "20,000 hours maintenance-free" marketing myth. While the laser light source may last that long, the system supporting it does not.

Sealed Optical Blocks: Even IP5X/IP6X "sealed" engines are rarely impervious to fine particulate matter like chalk dust or skin cells. Once dust migrates inside a sealed block, it requires clean-room level disassembly to rectify.

Liquid Cooling Maintenance: Flagship models from Panasonic (PT-RQ series) and Christie (Griffyn/Crimson) use glycol-based liquid cooling. Over 3-5 years, this coolant can degrade, evaporate, or develop sediment that blocks the micro-channels on the laser heatsink. Our service includes a complete coolant flush and pump performance verification.

4K Pixel Shift

We service the delicate actuator glass (e-shift) in 4K units that often develops a "buzzing" fault due to dust imbalance.

Phosphor Wheels

We inspect and clean phosphor wheels to prevent ceramic degradation and high-pitch bearing whine.

We Service Top Tier Models:

- Panasonic: PT-RZ, PT-RQ, PT-MZ Series

- Christie: D Series, GS Series, Crimson

- Barco: F-Series, UDX, G60

- Sony: VPL-GTZ, VPL-FHZ Laser

- Epson: EB-L1000 to EB-L30000 Series

University Case Study

Real World Scenario: The Cost of Neglect

A major London university skipped maintenance on their fleet of 20 Panasonic PT-RZ970 laser projectors for 4 years. The radiators became 80% blocked with dust.

The Result: The units ran 15°C hotter than spec. The lasers dimmed to 50% brightness prematurely, and 3 units suffered total laser bank failure requiring £4,000 repairs each.

The Solution: We implemented an annual deep-clean contract. The remaining units were restored to 85% brightness, saving the university over £60,000 in premature replacement costs.

The Deep Clean Process

We don't just blow air around. We strip the unit down to the chassis.

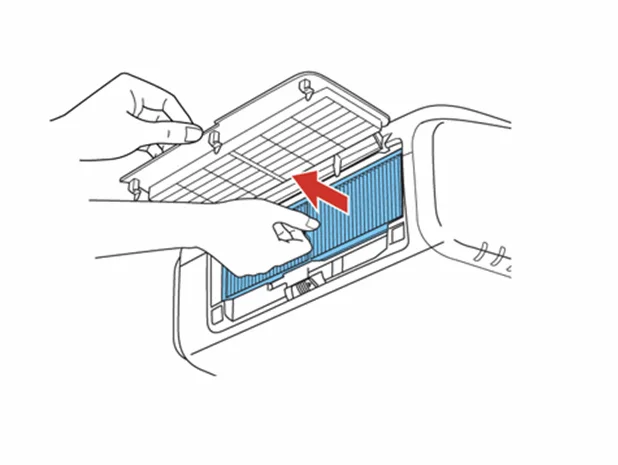

Internal Strip

Complete disassembly to access the deep air channels often missed by standard servicing.

Sonic Cleaning

Fans and airways are ultrasonically cleaned to restore laminar airflow and reduce turbulence.

Paste Renewal

Application of Artic Silver or industrial equivalent thermal compound to heat-critical chips.

Stress Test

3-hour full brightness soak test monitoring internal temperatures to verify stability.

Ready to Revive Your Fleet?

Whether it's a single home cinema unit or 100 classroom projectors, our maintenance service is the smart choice.

Free Collection & Return options available for bulk orders.